Gravimetric & volumetric feeder | Schenck Process

Our volumetric feeders are the ideal choice for applications that require economic feeding solutions. Quickly assembled and dissembled, they are seamlessly integrated into existing production lines and easy to maintain. Additionally, our gravimetric feeders adjust feeding speed based on output demand, meaning your whole process is much more ...

gypsum hopper weigh feeders- Crusher Machine

Feeder and weigh hopper "dead load" are mass-counterbalanced so that only material weight (live load) is measured. This feature helps assure excellent control in "noisy" environments. GYPSUM,OXIDE PELLETS, LWF-HC-V CONSULT FACTORY 400 4,000 CONSULT FACTORY CUSTOM CUSTOM CUSTOM CABLE SG LVDT YES GLASS …

MULTIDOS® H

Possible Applications: E3 Feeding of chunky, granular bulk materials (e.g., clinker, gypsum, lump coal) Feeding of all powdery or mealy bulk solids (e.g., raw meal, fly ash, filter dust) …

Weigh Belt Feeders | SRO Technology

Types of feeders: Volumetric weigh conveyors allow a certain volume of material to pass onto a conveyor within a specific timeframe.These solutions are ideal when a product's density is consistent, and are very effective at dealing …

Hopper Discharge Systems

Chart of conveying capacity type KZB-S and type BPB-S. Width P/w (mm) 1,000. Standard layer height H (mm) 400 +/- 100. Conveying speed (m/s) 0.05 0.10 0.15 0.20 64 +/- 16 …

Rotary Discharge Machine

can be achieved with the Weigh Feeders. Storage capacity 9,000 t Material limestone and marl of 0 – 60 mm Humidity max. 14 % Capacity of each discharge machine 30 – 180 t/h Installed power 20 kW Rotating speed of discharge wheels adjustable from 0.5 to 5 rpm Travel speed 1 and/or 0.45 m/min Weigh belt feeder width 800 mm

technical specification for belt weigh feeder

of 2. Match case Limit results 1 per page. TECHNICAL SPECIFICATIONS OF BELT WEIGH FEEDER 1. Capacity : 110 TPH 2. Feed Rate : 60-90 TPH (normal working range) 3. Material : Crushed Copper Ore 4. Flow Characteristics : Continuous 5. Material Size : (-12) mm 6. Moisture Content : 4% 7.

pfister rotor weighfeeder dosimate calinker cement mill

weigh feeders for cement plant - beltconveyers, ... Ball Mill, Cement Granulator, ... schenck weigh feeder for Cement industry | Clinker Grinding Mill. ... pdf manual rotor weighfeeder pfister. Go to Product Center. rotor raw mill - Crusher, ... Change rotor weighfeeder trw-k efficient impeller ...

MDL Heavy Industry Weigh Belt | Thayer Scale

Thayer Scale's Model MDL Weigh Belt is widely recognized mainline industrial continuous weigh belt feeders. They can be used with an open loop belt drive to gravimetrically totalize and measure the flow of material, or with closed control as a feeder and regulate the flow to a constant or varying set point. The Model MDL bridges the gap ...

Gravimetric & volumetric feeder | Schenck Process

We test our highly accurate volumetric and gravimetric feeders with over 4000 bulk materials to ensure each one correctly identifies and quantifies your material weight - even for substances such as coal where bulk density variations are common.

CIRECUTE | PDF

CLINKER WEIGH FEEDER GYPSUM WEIGH FEEDER LIMESTONE FEEDER. MILL INLET FEED BELT GYPSUM HOPPER. LIMESTONE FEEDER. CEMENT MILL. You might also like. 325256-00-ED-PR-BLD-0001-A02[02] 325256-00-ED-PR-BLD-0001-A02[02] Javad Monfared. Flow Process Nvl. Flow Process Nvl. Nauval Ahmad. PL FORMS.

Calibration Report | PDF

Calibration Report - Free download as Excel Spreadsheet (.xls / .xlsx), PDF File (.pdf), Text File (.txt) or read online for free. weigh feeder

Designing a Hopper

7. The minimum length of the feeder is determined by projecting the angle of repose for the specific material from the gate point (see illustration titled "Ideal Hopper Design") to the feeder pan, and adding 4 to 6 inches to …

Export Data and Price of GYPSUM under HS Code 8474 | Zauba

View detailed Export data, price, monthly trends, major exporting countries, major ports of GYPSUM under HS Code 8474 . Skip to main content. Toggle navigation . Import Export Data . India. Import Export Data; HS Code Search ... GYPSUM WEIGH FEEDER-10 TPH(EQUIPT NO.532 WF3) Tanzania: Nhava Sheva Sea: NOS: 1: 463,750: 463,750: …

Weighfeeder Application Guidelines

1. Weighfeeder (with weigh scale and speed sensor) Weighfeeders monitor and control the flow rate of gravity fed material from a pre feed device such as a bin or conveyor 2. Integrator Integrators collect the data from the weighfeeder and output: – Flow rate (max. & min.) – Belt load – Belt speed – Totalization 3.

m/sbm clinker weigh feeder.md at main · legaojm/m

Contribute to legaojm/m development by creating an account on GitHub.

I-P-1.01-W-7 (Weigh Feeder) | PDF | Calibration | Weight

1.1.1 Weigh feeder must be selected in Volumetric mode. 1.1.2 Belt should be Empty condition. 1.1.3 TARE ADJUSTMENTS : 1.1.3.1 Start Weigh Feeder at full speed without weight. Set point must be ( P value in TPH ) ... GYPSUM WEIGH FEEDER-2 CAPACITY 40 TPH

Technical Sheets

Embedded digital weigh system Speed control system of the feeding movement Inspection doors to ease maintenance Function: The MAMMUTHUS is a device used both as a strong apron feeder and as a common weigh belt feeder. The speed is controlled according to the material load in order to obtain a constant and accurate fl owrate.

Products

Open Design Weigh Feeder Stucco Gypsum Weigh Feeder. Weigh Feeders: Belt Scales . Train Loading Systems . Loss-in-Weight Feeders: Other Products: Electronics: Accessories:

Gypsum

Gypsum plants use our E Series Even Feeders to feed air swept mills, replacing vibratory feeders and air locks. Even feeders eliminate the turbulence and inconsistent flow that …

(XLSX) Load Cells for W.feeders

Load Cells for W.feeders. of 4. QATAR NATIONAL CEMENT COMPA UMM-BAB CEMENT P PURCHASE REQUI Store Incharge QNCC Umm-bab Please prepare Supply Order on M/S SCHENCK Process Fax : +49 (0)615132-3632 E-Mail : bvk.process@schenc M/S STREAM Doha Fax : 44322193 OR Any Local Supplie for the follwing items required for …

Pfister VRW rotor weigh feeder

The series of rotor weigh feeders continues with the special models FRW for metering fine products, such as cement raw meal, fly ash, bypass dust and kiln dust, and the TRW weigh feeder that is offered for weighing coarse products, such as cement clinker, raw coal, gypsum and limestone.

Which is better: a volumetric or gravimetric weigh belt feeder?

Gravimetric weigh belt feeders, meanwhile, are closed loop devices that continuously weigh material passing over the belt, and communicate this data back to the controller. This means speed corrections are made automatically to the setpoint rate. ... For example, plasterboard producers need to add a precise amount of gypsum to each mold during ...

Addition Of Gypsum In Grindid Clinker | Crusher Mills, Cone …

WEIGH FEEDER: E-DBW-A : with own discharge belt and speed-controlled drive … above all are used for metered addition of additives in the gypsum… density of gypsum and clinkar for cement plant Gulin provide the density of gypsum and clinkar for cement plant solution case for you. …

gypsum feeder china

Contribute to dinglei2022/en development by creating an account on GitHub.

Pelleting Chemical Powders

Pelletize powder additives to improve their bulk density and allow for improved subsequent processing. Create spherical pellets of absorbents resulting in enhanced absorption. Achieve better dosing with easier to handle pelletized form from powders. Develop spherical pellets with narrow particle size distribution allowing for better gas flow in ...

Low to Medium Capacity Feeder

The Thayer Scale Model "MTF" weigh feeder (Low to Medium Capacity Feeder) designed to process a range of materials from ceramic mix to gypsum is a low to medium capacity feeder that accurately and reliably measures and controls material feed rates. It is available in widths from 18" to 48", and adaptable in length and width to meet the customers' …

Apron Weigh Feeder

the AUMUND Weigh Feeder offers the definite advantage of combining two steps of the production process in one single machine. Weigh Feeder type DPB Arched Plate Pan Conveyor type BPB 3 Pan width/ height Weigh feeder dimensions (mm) 800 / 200 1.000 / 200 1.200 / 200 1.400 / 200 1.600 / 200 A 800 1.000 1.200 1.400 1.600 B 600 800 1.000 …

Product Brochure Pfister TRW / TRW-K

weighing and dosing principle of all Pfister® rotor weigh-feeders is identical: Material is extracted out of the material silo and is trans-ported in the rotor chambers (1) from the inlet (2) to the ... Bulk materials such as limestone, gypsum, pre-ground cement, clinker Dosing capacity: Up to 400 t/h Design example: - Calibration pre-hopper

Gypsum, crushed volume to weight conversion

About Gypsum, crushed; 1 cubic meter of Gypsum, crushed weighs 1 602 kilograms [kg] 1 cubic foot of Gypsum, crushed weighs 100.00959 pounds [lbs] Gypsum, …

Specifications

Specifications - Schenck Weighing Systems

Dosage, Agitation, Filtration, Malaxage Dosing

In today's competitive environment, accurate, reliable and low-maintenance equipment helps your profitability. Whether your application is in Cement, Aluminium, Glass, Steel, Fertilizer, Gypsum & Plaster, Mines & Quarries or any other continuous industrial processes, you can benefit from our wellproven equipment, know-how and human size ...

Cement Manufacturing Process | HeidelbergCement India Limited

The proportioning of clinker, gypsum and HRS is done by electronic weigh feeders. Clinker and gypsum are pre crushed in a Roller press and subsequently fed into Cement mill for fine grinding. Cement Packing . Cement is packed by high efficiency rotary packers which are electronically controlled. Packers are highly precise with tolerance of ...

MTF Weigh Belt Low to Medium Capacity Feeder

The Model "MTF" weigh feeder is a low to medium capacity feeder that accurately and reliably measures and controls material feed rates. It is available in widths from 18" to 48", with different belt types, standard inlet …

schenck clinker weigh feeder india

Contribute to jidafang2022/en development by creating an account on GitHub.

Control of Weigh Feeder by Programmable Logic Controller: …

A weigh feeder in a cement industry is used to continuously feed bulk solids for grinding; these solids are clinker, gypsum and fly ash in 72.5, 2.5 and 25 percentage respectively. So weigh feeder is actually a conveyor belt through which material passes and is dropped to the mill for grinding. ...

MULTIDOS® H

A broad spectrum of active and passive bulk material feeders that are specially designed for specific bulk material properties supports the wide range of possible applications. ... clay, marl, gypsum from flue gas desulfurization systems) ... high-end continuous weigh belt 13 Automatic belt cleaning system (both sides) 13 Belt influence ...

Gypsum volume to weight conversion

Gypsum weighs 2.96 gram per cubic centimeter or 2 960 kilogram per cubic meter, i.e. density of gypsum is equal to 2 960 kg/m³; at 20°C (68°F or 293.15K) at standard …

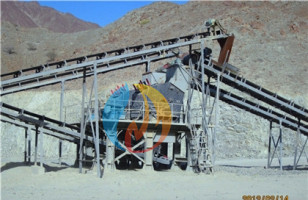

- consultants for apron feeder and primary crusher

- motorised vibratory feeder manufacturer india

- vibrating hopper feeder price

- namdeb apron feeder treatment plant front

- Calculation Of Motor Power For Feeder

- screw sand feeder

- apron feeder magnesium

- vibrating feeder treatment

- wobbler feeder enclosed

- coal handling feeder

- apron feeder for river stone sand making plant in nigeria bw apron feeder

- apron feeder bwh

- crusher feeder table

- retractable vibro feeder emi

- how amplitude of vibro feeder is measured

- manganese mountain feedermetalliferous mining appron feeder

- grizzly mining feeder price

- screw feeder for sand

- vibrating conveyors chipper feeder

- low vibration feeder

- vbration feeder

- gold ore crusher with 3 feeder hopper

- belt feeder supplier

- long vibrating feeder

- screw feeder screwdriver

- c12 spare parts vibrating feeder jaw crusherhow does a vibratory screen work

- vibating feeder

- vibratory feeder manufacturers in faridabad

- wobbler feeder specified