The Aggregate Production Function

production function is a mathematical relation between inputs and output that makes this idea concrete: Y = AF(K;L); where Y is output (real GDP), K is the quantity of physical capital (plant and equipment) used in production, L is the quantity of labor, and A is a measure of the productivity of the economy (we call it total factor productivity ...

Production of Aggregate | PDF | Mill (Grinding) | Industries

PRODUCTION OF CRUSHEDSTONE AGGREGATE. In operating a quarry and crushing plant, the drilling pattern, the amount of explosives, the size shovel or loader used to load the stone, and the size of the primary crusher should be coordinated to assure that all stone from the quarry can be economically utilized. CHAPTER 14.

4 Particle Analysis Instruments Used for Testing …

When it comes to particle analysis, there are four pieces of aggregate testing equipment used throughout the industry: sieve shakers, screening machines, air jet sieves, and dynamic image analysis …

Concrete | Definition, Composition, Uses, Types, & Facts

concrete, in construction, structural material consisting of a hard, chemically inert particulate substance, known as aggregate (usually sand and gravel), that is bonded together by cement and water. Among …

5 Types Crushing Equipments For Sand And Aggregate | M&C

5 Types Crusher Equipments For Sand And Aggregate Production Line. Crusher equipment can be divided into 2 categories according to its working principle: Extrusion crusher equipments, such as jaw crusher, rotary crusher, cone crusher, etc. It is suitable for crushing raw materials with a high abrasion index.

How to Produce High-Quality Construction Aggregates?

The Significance of High-Quality Construction Aggregates Production. 60%-70% of the contents of concrete are aggregate. Whether it is fine aggregates or coarse stone aggregates, proper aggregate gradation has a direct and good influence on the concrete workability, strength, impermeability, frost resistance, corrosion resistance, and …

11.20 Lightweight Aggregate Manufacturing

are also used to heat the raw material. In addition, a few plants process naturally occurring lightweight aggregate such as pumice. 11.20.2 Emissions And Controls1 Emissions from the production of lightweight aggregate consist primarily of particulate matter (PM), which is emitted by the rotary kilns, clinker coolers, and crushing, screening, and

Aggregate Production Equipment | Material Handling | Kemper

At Kemper Equipment, we listen, consult, create, and solve problems for our valued clients in the aggregate processing and material handling industries. Today's blog post showcases one of our recent success cases to show you what improved production actually looks like in practice. Kemper recently custom-designed a new plant for a ...

Greenhouse Gas Emissions from Asphalt Pavement …

The GHG emissions of asphalt pavement consists of those from the machines and equipment used in the construction process. It is calculated by multiplying the energy consumption data (AD) by the emission factor (EF) of each energy type, fuel or electricity, as shown in Equation (4). ... The aggregate production data was already …

Production of Aggregate

fCHAPTER 14. AGGREGATE PRODUCTION. In operating a quarry and crushing plant, the drilling pattern, the amount of explosives, the size shovel or loader used to load the stone, and the size of the primary crusher should be coordinated to assure that all stone from the quarry can be economically utilized. CHAPTER 14.

(PDF) Production of Aggregate

7/30/2019 Production of Aggregate 1/33 A. J. Clark School of Engineering Department of Civil and Environmental EngineeringSixth EditionCHAPTER14Construction Planning, Equipment,and…

Aggregates Production Equipments "aggregates

Aggregate Screening Plant is baseful aggregate production machine / equipment for aggregate … Because of the greater porosity oflightweight aggregates … Because of the greater porosity oflightweight aggregates, follow these procedures to ensure production of top-quality concrete masonry units

equipment used in production of aggregate

Joyal sand making equipment used in concrete aggregate ..., Joyal sand making equipment used in concrete aggregate production ... concrete is an integral part of the production system. Sand aggregate is an important ... Go to Product Center. Construction, concrete, forestry, and mining equipment pictures, ... MINING, AND AGGREGATE …

Chapter 13 Flashcards | Quizlet

d. A firm's demand in the next four quarters (its aggregate planning horizon) is forecast to be 80, 50, 40, and 90 units. Last quarter, the firm produced 60 units. If it uses level scheduling, the firm will. a. hire workers to permit production of 65 units per quarter for the next four quarters. b. hire 20 workers.

Aggregate Equipment That Produces High-Quality …

Fine aggregate is 4.75mm or smaller as it can pass through a #4 sieve. Coarse aggregate is greater than 4.75mm and is retained by a #4 sieve. Fine aggregate is usually finely crushed stone, sand, silt, or clay. It's …

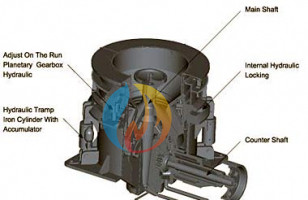

Crusher equipment models and their applications

The crushed material is discharged at the bottom of the machine after they pass through the cavity. Cone crushers are popular rock crushing machines in aggregate production, mining operations, and …

Text of aggregate equipment production

production aggregate equipment 95 Aggregate is a component of a composite material used to resist compressive stress and provide bulk to the composite material. For efficient filling, aggregate should be much smaller than the finished item, but have a wide variety of sizes. It is vastly used in most combination of construction material such as concrete and …

Los Angeles Abrasion – Pavement Interactive

Afterward, the aggregate is removed from the drum and sieved on a No. 12 (1.70 mm) sieve. The aggregate retained on the sieve is weighed and the difference between this weight and the original weight is expressed as a percentage and reported as the L.A. abrasion loss value. Figure 11 shows major equipment used in the L.A. abrasion test.

A Brief History Of Concrete And Aggregate Equipment

Aggregate Equipment Today. Technology has made the extraction, production, and transportation of aggregate much easier. We no longer rely on people hammering with …

Types of Concrete Equipment for different project applications

Discussed below are different types of concrete equipment used across projects in India. Concrete batching plant. A concrete batching plant combines various ingredients to form concrete. Some of the ingredients used include water, air, admixtures, sand, aggregate (rocks, gravel, etc.), fly ash, silica fume, slag, and cement.

The Aggregate Manufacturing Process | General …

General Kinematics equipment stands out from average aggregate feeders, screeners, and sorting equipment due to GK's ability to create high performance, low maintenance, …

The Essential Guide to Aggregate Equipment in Construction

There are four main types of equipment used in aggregate production. All are discussed below. Crushers: Crushers are used to break down large rocks into smaller sizes, which are then further processed into aggregates. Screens: Screening equipment …

Custom Aggregate Design & Build Services | Kemper Equipment

Kemper Equipment has successfully completed thousands of aggregate and mineral processing system designs and engineering projects, including retrofits, new aggregate production plant installations, and railcar and barge loading/unloading aggregate conveyor systems integrations. Every member of our highly-trained staff knows what it takes to ...

Aggregate Resources | WA

Sand, gravel, and bedrock may be mined or quarried to produce raw materials known as 'construction' aggregate. Construction aggregate is used for road base and stabilization as well in the manufacture of concrete, asphalt, and other products. These products are the building blocks for our homes, businesses, roads, and bridges. Examples of the …

Aggregate Production Process | Cornerstone Aggregates Inc.

QUARRYING. This is an essentials stage in the production process, because the quality of the aggregates produced depends on it. This is our consideration when we applied for our concession. The choice and selection of the source on the basis of its physical properties are decisions of strategic importance.

Aggregates for Concrete as per American Standards – ASTM [PDF]

Reading time: 5 minutes. The aggregates used in the production of concrete are inert granular materials such as gravel, crushed stone, sand, slag, recycled concrete, and geosynthetic aggregates. The aggregates may be natural, manufactured, or recycled. Fig 1: Aggregates used in production of concrete. The aggregates are broadly classified into ...

Inspection & Sampling Procedures for Fine & Coarse …

The following equipment and supplies are deemed necessary to properly perform the various required tests for aggregate inspection. The technician will have on hand, or have access to sufficient quantities of these supplies or equipment before attempting to conduct tests. LABORATORY General Equipment required for various general procedures:

Aggregate Equipment For Sale

Aggregate equipment covers a wide range of product types, including conveyors, feeders, stackers, crushers, and screens. Aggregate Equipment For Sale 1 - 25 of 7,028 Listings …

All About Concrete And Aggregate Equipment | Sepro

The aggregate used can include sand, gravel, crushed stone, or recycled concrete. Different aggregates will be selected, depending on the application of the concrete. To …

Aggregates for Concrete

aggregate and crushed stone coarse and fine aggregate are produced by crushing natural stone. Crushing, screening, and washing may be used to process aggregates from either sand and gravel deposits or stone quarries. Aggregates may be produced from igneous, sedimentary, or metamorphic rocks, but geological type does not by itself make an …

5 Types of Equipment Used for Aggregate Crushing

5 Types of Equipment Used for Aggregate Crushing. January 27, 2021. Aggregates are mostly made from materials that can still be used in various projects and …

Common Types of Concreting Equipment Used in Construction

Here are some of the most common concrete equipment used in construction: 1. Concrete Batching Plant. Also known as concrete plant, this equipment mixes various materials to form concrete. These materials include sand, aggregate, slag, cement, fly ash, and water among others. Concrete batching plants come in various …

TOOLS AND MACHINERY USE FOR THE CONCRETE PRODUCTION AND SUPPLY

In plant, the batching process done by combination of heavy machineries because of the requirement of larger quantity of concrete. Here we use, 1.Moving belt 2.Crane 3.Water pumps/tank 4.Mixer truck 5.Screw conveyor 6.Excavators 7.Power generator 8.Hydraolic pump 9.Mixer 10.Power motor 11.Air compressor.

11.19.1 Sand And Gravel Processing

or diesel also may be used. After drying, the material is cooled and then undergoes final screening and classification prior to being stored and packaged for shipment. 11.19.1.2 Emissions And Controls6-14 Emissions from the production of sand and gravel consist primarily of particulate matter (PM)

MQM 227 Exam 2 Flashcards | Quizlet

Study with Quizlet and memorize flashcards containing terms like 1. Which of the following statements is incorrect? a. Aggregate planning involves planning at a specific product/service level not a product family level. b. Scheduling decisions allocate available capacity or resources (equipment, labor, and space) to jobs for a given period of time. c. …

How Does A Sand Classifier Work? | Aggregates Equipment, Inc.

As concrete mix specifications change, so too must the aggregate used in its production. Globally, the trend has been a push towards a cleaner sand product – one with fewer contaminants. With tighter demands on sand for concrete production, equipment used for screening the sand must become more efficient.

- beneficiation equipment slag

- oil sands mining equipment suppliers

- copper mining conveyor equipment

- gypsum mining equipment

- gold miner equipment price eu

- refractory materials crushing equipment

- quartz crusher equipment

- washing sand equipment

- peat perlite equipment

- manufactured sand equipment

- ore processingore processing equipment

- equipment to grind rocks

- electroflux equipment

- caiman crushing equipment co ltd in tamilnadu

- pre used iron ore processing equipment equipment

- iron ore mine equipment suppliers

- processing equipment project

- gemstone mining equipment suppliers thailand

- ranking of worlds largest manufacturer of construction and mining equipment

- beneficiation of copper iron and aluminum oresaluminum ore processing equipment

- early coal mining equipment

- organic waste disposal recycle process equipment

- Pre-start Check List For Mining Equipment

- crushing plant equipment for sale in ghana

- supplier of crusher equipment in brazil

- clay mining equipment

- slag screening equipment company

- galeo equipment mining

- broken glass milling equipment