ZY High Efficiency Series

ZY High Efficiency Series. Contact Us +86-373-3663285 +86-373-3663296. info@cementcrusher. ... Crusher Machine. Jaw Crusher; Fine Crusher; Cone Crusher; Impact Crusher; Fine Crusher; Teeth Roller Crusher; ... Mobile Jaw Crushing Plant; Sand Making Machine. 5X Vertical Shaft Series;

Jaw Crusher: Range, Working Principle, Application

Jaw Crushers are configured for primary crushing of even hardest rock. Our Jaw Crushers are crushing without rubbing Minimum dust Oil lubrication, devise having Oil/Grease lubrication system. The company crushers are designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity.

Jaw Crusher | Crushing Plant | Hard Rock Mining Equipment

DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPa.DOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration.. …

6 Granite Crushers for Efficient Granite Rock Crushing

Jaw Crusher Due to the large feeding inlet and strong crushing capacity, jaw crushers can crush bulky granite rocks (above 450mm) into smaller sizes. It is an efficient primary granite crusher. The fine crushing jaw crusher developed by Ftmmachinery can carry out fine crushing of granite stones.

CZS High-efficient Cone Crusher

CZS High-efficient cone crusher is a high-performance type optimized and improved on the basis of PY series spring cone crusher. It is widely used in fields of mining, building material, metallurgy, etc. It is suitable for medium crushing and fine crushing on basalt, river stone, granite, quartz, metal ore, etc with high hardness materials ...

Coarse Crushing Cone Crusher Or Jaw Crusher Is Better

The cone crusher is suitable for coarse crushing of various hard and brittle materials with large output. The design of the deep V crushing cavity of the jaw crusher prevents the material from being blocked in the crushing cavity, which can effectively improve the production efficiency. Jaw Crusher and Cone Crusher, these two kinds of …

Crushing 101 » Masaba Manufacturing

The width of the jaw determines capacity. Jaw crusher output gradation is controlled by the closed side setting. This is the adjustable opening at the bottom of the jaw. With a 24" top size limit and an 8:1 …

Jaw Crusher for Hard Materials | DASWELL

Advantages of Daswell jaw crushe. 1. The structure is simple and firm, and the production is efficient. Daswell jaw stone crusher has a relatively firm frame and can work under high pressure. The weight of the equipment is about 15% heavier than other manufacturers, and the structure is stronger and more impact-resistant.

Jaw Crusher Efficiency Factors

The factors affecting the efficiency of jaw crusher in production are as follows: … jaw crusher, impact crusher and fine crushing machine. ... Impact crusher is high-efficiency crushing … Jaw Crusher Performance: jaw crusher force analysis – Gold Ore Crusher. This video illustrates single- and double-toggle jaw crushers. Sand ...

What Is The Best Limestone Crusher | Limestone Crushing

Impact Crushers. Impact crushers are widely used in the crushing of various minerals and rocks, and are particularly suitable for the crushing of limestone with a low to medium hardness. They are characterized by a large crushing ratio, high efficiency, and good grain shape.

Fine Jaw Crushers

The fine jaw crusher range includes: Essa® JC1250 Fine Jaw Crusher – the scaled down and more affordable version of our fine jaw crushers. Evolved from an intensive two-and-a-half-year research and development program to present power and value for high workload crushing. Clever design makes it easy for you to control product sizing.

Grinding Mill,Stone Crusher Machine,Sand making machine …

DBM Machinery Can Supplier your the best Grinding Mill,Stone Crusher Machine,Sand making machine price,Mobile Crusher Plant,Jaw crusher,impact crusher,Cone crusher,ball mill,complete stone crusher plant for you, if you have any question, PLZ contact us,we will give you the best help! ... high-efficient fine crush. More. New Fine …

Granite Crusher | Granite Stone Crushing Plant

The jaw crusher is used for the primary crushing of granite, and the impact crusher is used for the integral crushing, so as to achieve the crushing effect of excellent grain shape. For the granite stone crushing plant with large output, the three-stage crushing machine should be used as far as possible, the jaw crusher + fine jaw …

How to Optimize Reduction Ratio in Jaw Crusher?

The reduction ratio is a critical parameter for the performance of a jaw crusher. It affects the capacity, quality, and energy consumption of the machine. A high reduction ratio means a smaller …

New High-Efficiency Jaw Crusher with Flexural Extrusion Crushing …

Jaw crushers are mainly used for medium and fine crushing of raw materials, such as coal, coal gangue, coke, limestone, pyrite, phosphate rock, etc. The crushing method is flexural extrusion. The maximum size of the crushed material should be less than 10--60 mm of the size of the nozzle of the selected machine model.

Baichy Heavy Industrial Machinery Co., Ltd

Baichy is a factory supplier of mining machinery, mainly focused on Stone crushers, Mobile crushing plants, Powder grinding mills, and Mineral processing equipment. Contact us 86

Choosing the Right Jaw Crusher Size and Capacity …

Maximizing crusher performance and productivity requires selecting the right jaw crusher size and capacity. Learn how to determine the optimal size and capacity for your application, and discover the …

High Efficiency Fine Jaw Crusher

Type: Jaw Crusher Application: Mineral Industry Drive: Electric Crushing Style: Extruding & Milling Compressive Strength (For Crushing): 250-300MPA Crushing Degree: Coarse Crusher

How to Optimize Reduction Ratio in Jaw Crusher?

The reduction ratio is a critical factor in determining the efficiency of a jaw crusher, as it directly affects the size and capacity of the machine. In this article, we'll explore what reduction ratio is, why it's …

Jaw Crusher | Crushing Plant | Hard Rock Mining Equipment

DOVE Jaw Crushers are highly popular, since they can process large volume of hard rock efficiently, and due to their small physical size design, high efficiency, …

CZS High-efficient Cone Crusher

CZS High-efficient cone crusher is a high-performance type optimized and improved on the basis of PY series spring cone crusher. It is widely used in fields of mining, building material, metallurgy, etc. It is suitable …

TWP Efficient Fine Crusher

TWP-Efficient Fine Crusher TWP Efficient Fine Crusher is a newly developed fine crushing equipment for special materials, which is developed by our company. It adopts the most advanced crushing technology of both domestic and abroad with the features of unique structure, high efficiency and energy saving. And this crusher owns two national ...

High-capacity crusher, High-capacity crushing plant

jaw crusher SLU - 1400. mobile high-capacity. Capacity: 0 kg/h - 600 kg/h. SPECIFICATIONS Capacity up to 600 Kg/h Application for Big-bags, PET, film Shaft diameter 400 mm Power of the actuating motor 45 KW Actuating motor speed 1470 rpm Shaft speed 970 rpm Clearance ...

Stone Crusher In Ethiopia

Jaw crushers can crush all types of rock, including the hardest granite, brick, concrete and asphalt. Ethiopia stone jaw crusher has high reduction ratio and increased capacity with any feed ...

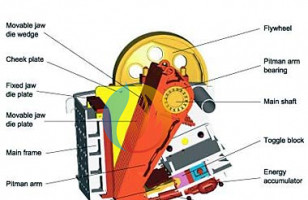

Problems with Toggle Plates in Jaw Crushers and How to Fix …

Problem 1: Broken toggle plate. A broken toggle plate is a serious problem that requires immediate attention. The first step is to shut down the jaw crusher and ensure that all power sources are disconnected. Once the machine is safe to work on, the broken toggle plate should be removed. Depending on the design of the jaw crusher, this may ...

Aggregate Crushers

Jaw Aggregate Crushers – Large Feeding Port For Crushing Large Materials. Aggregate jaw crusher is mainly used for processing bulk material. Its maximum feed size can …

Crushing Efficiency Hammermill | Crusher Mills, Cone Crusher, Jaw …

Advanced Hammermill Crusher for stone Processing In Pieces. High efficiency, low energy consumption; Suitable for …. Hammermill without Cyclone and Electric Motor Electric …. The main components are sieving part, chips re-crushing ….

Jaw crusher_The NIle Machinery Co.,Ltd

Capacity (t/h) : 1-800. The scope of application is wide. Jaw crusher is widely used in mine industry, smelting, building materials, roads, railways, water industry, chemical industry, etc. and is especially suitbale for a stationary crushing production line and a mobile crushing station. Email: [email protected] Whatsapp: +86-.

what jaw crushers speed rpm should do

Crusher Design: The design of the crusher itself, including the geometry of the crushing chamber and the eccentric throw of the movable jaw, can impact the ideal …

High Efficiency Jaw Crush

Create fine powders for industrial projects with crusher machines. Browse the high efficiency jaw crush range on Alibaba for all types at wholesale prices. MENU ... Hard Rock Processing Mobile Small Jaw Crusher Machine Stone Crusher For Agricultural Usage $1,400.00 ...

Crushing Efficiency

Mechanical Operations Questions and Answers – Crushing Efficiency. « Prev. Next ». This set of Mechanical Operations Multiple Choice Questions & Answers (MCQs) focuses on "Crushing Efficiency". 1. Which of the following works on principle of compression and impact? a) Jaw crusher. b) Gyratory crusher. c) Fine crusher.

The Efficiency Of Impact Crusher(pdf)

Impact Crusher- Heavy Industry – Crusher & Mill, Jaw … Impact Crusher can crush many kinds of materials with max feed size less than 500mm and crushing strength less … high efficiency, low consumption; …

Aggregate Crushers

Aggregate jaw crusher is mainly used for processing bulk material. Its maximum feed size can reach 1200mm*1600mm, which can meet the needs of processing large pieces of construction waste aggregate. AIMIX's jaw type aggregate crusher adopts a cast steel frame and movable jaw, which has high strength and long service life.

Crusher

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer …

The Ultimate Guide to Designing an Efficient Aggregate Crushing …

Introduction. An aggregate crushing plant is a machine that processes a wide range of raw materials into high-quality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges. Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and …

Jaw Crusher VS Cone Crusher: 9 Key Differences

The cone crusher has large crushing ratio, high efficiency, low energy consumption, uniform product size, and is suitable for medium and fine crushing of …

Crushing Efficiency Of Jaw Crusher | Crusher Mills, Cone Crusher, Jaw

Jaw crusher,high- efficiency jaw crusher, rock crushing expert. Jaw crusher is mainly applied to crush the materials whose pressure resistance strength is under 320 Mpa. It is suitable for primary crush.

Assessing the energy efficiency of a jaw crusher

As an indirect jaw crushing parameter, the choke feeding intensity was also emphasized by Beloglazov and Ikonnikov [40]. As the rock comminution and energy efficiency can be defined as a function of area increment of particles in jaw crusher [41], the production of fines can be diminished by regulating the mf in the crushing chamber.

Jaw Crushers – MEKA

The greater the number of oscillations of the jaw, the more fine product is produced. In high oscillating crushers, the jaws open and close more often and ore does not have the …

- high pressure lamp

- high pressure suspension girnding mill producers in china

- wet high national

- high intensity addit

- best seller and high quality jaw crusher

- bismuth high pressure roller grinding

- high performance jaw stone crusher

- high quality iron

- high pressure drier

- high pressure roller press grinding in cement plant

- high intensity election

- high pressure conveyed

- retention recovery and recycling of metal values from high alloyed steel slags

- high quality with resonable ore jaw crusher pioneer jaw crusher

- high intensity processing

- high pressure tests

- high frequency high

- grinding high cement

- high speed mining conveyor

- jaw crusher with high production efficiency

- high gradient producer

- grinding high machinevertical

- high pressure laminate

- high cr impact blow bar

- high quality crushing plant

- high pressure grinding mill flow diagram

- sand high pressure moulding machine

- bmw crusher high quality

- high chrome grinding media ball