Idaho Transportation Department

Idaho IT 144 Specific Gravity and Absorption of Fine Aggregate Using Automatic Vacuum Sealing (CoreLok) Method : AASHTO T 19 Bulk Density ("Unit Weight ") and Voids in Aggregate ... of natural sand from the unproven source (3,000 to 5,000 grams). 5.1.1. The sand is moistened to a point past SSD, then covered and kept moist for a minimumof ...

Suitability of Ambo Sandstone Fine Aggregate as an Alternative …

Relative to this, searching a source of new substitute of fine aggregate for concrete production, which can be replaced naturally or river sand is significant. In Ambo area, natural or river sand is rarely available because of its terrain and geographic location, while those available having low quality due to a mixture of sand and clay (i.e ...

Proficiency Sample Overview

AASHTO re:source's Proficiency Sample Program (PSP) is the largest construction materials sample program in the world, with a customer base of approximately 3,000 testing laboratories. ... At that time, four basic material types were included in the scope of the program: fine aggregate, coarse aggregate, soil, and asphalt binder. Currently, ...

Section 902 AGGREGATES

the source for a specific fine aggregate. Cobblestones (Cobbles). Rock fragments, usually rounded or semi-rounded, with an average dimension between 3 inches and 10 inches. ... The fine aggregate must meet the requirements of subsection 902.08. 902.04. Chip Seal Aggregates. For chip seal, use 34CS aggregate with ...

Difference Between Fine and Coarse

Fine Aggregate: Source: Fine aggregates are typically sourced from natural sand, manufactured sand (also known as crushed sand or M-sand), or a combination of both.

final report

Source: HOPKINGTON QUARRY Location: HOPKINTON, NH FINE AGGREGATE ANALYSIS REPORT - 2021 Lab No: 20210101 RHODE ISLAND DEPARTMENT OF TRANSPORTATION MATERIALS AND QUALITY ASSURANCE Sieve Analysis of Fine Aggregate Unit Weight and Void in Aggregate Specific Gravity and Absorption of Fine …

Aggregates for Concrete

Aggregates may be broadly classi fied as natural or artificial, both with respect to source and to method of preparation. Natural sands and gravels are the product of weathering and the action of wind or water, while manufactured crushed fine aggregate and crushed …

Water absorption of fine recycled aggregates: effective

A disadvantage of the conductivity method indicated in [44, 45] is that it uses a set up for direct conductivity measurement which might be significantly influenced by the quality of the contact with the terminals.In the case of crushed fine aggregates, the contact between aggregate particles and electrical terminals can be deficient due to the shape …

Fine Aggregates: Types, Properties & Uses in construction

Fine aggregate comes in a variety of forms, including sea sand, crushed stone sand, manufactured sand, and natural sand. The parameters of the concrete or mortar mix, as well as the location from …

Aggregates | Difference Between Coarse And Fine | How to do …

Fine Aggregates Are Any Particles Greater Than 0.19 Inch, but Generally Range Between 3/8 and 1.5 Inches in Diameter. Actually, that definition is not accurate. Fine aggregates are materials that pass through a 4.75 mm (No. 4) sieve and are typically smaller than 9.5 mm (3/8 in) in diameter.

Chapter 2

The required quality tests for each of these aggregate sources will be further discussed in this synthesis report. 2.4 Tests to Check Source Properties for Aggregate Quality Agency specifications for aggregate usage in pavement applications include requirements related to particle size distribution, degree of crushing (percentage crushed or ...

Fine Aggregates: Types, Properties & Uses in construction

It is used for concrete mix design and if not specified the specific gravity is taken as 2.7 because the specific gravity of most aggregates obtained from different sources falls between 2.6 and 2.8.. 5.Surface Texture of fine aggregates: Generally, round surface aggregates are better for smooth aggregates, this property is also related to coarse …

Sieve analysis of fine and coarse aggregate for concrete

Coarse aggregate: - Determine the weight of the sample of the aggregate which we have. 1. Nest the sieves in order of decreasing size of opening from top to the bottom, on plate over mechanical sieve shaker. 2. Drop the all sample (1461.0gm) on the highest sieve and switch on mechanical sieve shaker for short period. 3.

Solved 2. Using the Fuller maximum density equation (with an

You'll get a detailed solution from a subject matter expert that helps you learn core concepts. Question: 2. Using the Fuller maximum density equation (with an exponent of 0.45) what would be the ratio of coarse aggregate to fine aggregate for a concrete aggregate source with a 14 mm maximum size? Plot the full curve obtained.

Answered: To determine the moisture content,… | bartleby

Assume that the saturated surface dry SSD moisture conditions for fine and coarse aggregate are 1 percent and 2 percent, respectively. Determine the total free-water (extra moisture) in the concrete mix, if 220 kg of fine aggregate and 425 kg of coarse aggregate from the given source were to be used for preparing mix.

HOW TO CLASSIFY AGGREGATES ACCORDING TO SIZE?

Fine Aggregate. It is the aggregate most of which passes 4.75 mm IS sieve and contains only so much coarser as is permitted by specification. According to source fine aggregate may be described as: Natural Sand– it is the aggregate resulting from the natural disintegration of rock and which has been deposited by streams or glacial agencies;

SECTION 703

considered deleterious. Spent foundry sand may be used as fine aggregate in asphalt concrete and flowable fill. Obtain fine aggregate with physical properties conforming to …

SECTION 902 FINE AGGREGATE

Approval of construction aggregate sources shall be in accordance with 6-3. 902-1.2 Deleterious Substances: All fine aggregate shall be reasonably free of lumps of clay, soft or flaky particles, salt, alkali, organic matter, loam or other extraneous substances. The weight of deleterious substances shall not exceed the following percentages:

APPROVAL OF SOURCES OF FINE AND DOH 6 COARSE …

3. PROCEDURE FOR NEW SOURCE APPROVAL (THOSE NOT USED PREVIOUSLY BY THE DEPARTMENT) 3.1 Fine Aggregate 3.1.1 Upon receipt of a request for approval of fine aggregate from a new source, or one not previously used by the Department, Materials and Research personnel will visit the source and make a thorough evaluation …

Fine Aggregate in Concrete Mix Design: Types and Classification

The size of fine aggregate is defined as equal to or less than 4.75 mm. This means that the aggregates that can pass through a number 4 sieve with a mesh size of 4.75 mm are referred to as fine aggregates. These include clay, silt, and sand. Crushed gravel and crushed stone can also fall under this category.

Fine Aggregate — Material Testing Expert

What Can Fine Aggregate be Used for in Construction? Fine aggregate, also known as sand, is a crucial component in the construction industry. It is widely used in the production of concrete …

Aggregates

Fine aggregates generally consist of natural sand or crushed stone with most particles passing through a 3/8-inch sieve. Coarse aggregates are any particles greater than 0.19 …

Fine and Coarse Aggregates

Approved List Sources of Fine & Coarse Aggregates. The Materials Bureau also maintains the Materials and Equipment Approved List. The Materials Supplier Viewer contains the NYSDOT-Approved Sources of Aggregate for hot mix asphalt and portland cement concrete. Approved Sources can be viewed on the interactive map and/or exported as a …

Forms Aggregates

Course Aggregate for Source Approval (502) 95 KB Fine Aggr - Source Appr 278: Fine Aggregate for Source Approval: 82 KB 03-22-0745: 03-22-0745 Aggregate Test Report: Aggregate Test Report: 69 KB 03-22-0745: 03-22-0745 Aggregate Test Report: Aggregate Test Report: 2198 KB 03-22-0746: 03-22-0746 Deleterious Materials in …

Classification of Aggregates Based on Size and Shape -Coarse and Fine

The purpose of the fine aggregate is to fill the voids in the coarse aggregate and to act as a workability agent. Fine aggregat e. Size variation. Coarse Sand. 2.0mm – 0.5mm. Medium sand. 0.5mm – 0.25mm. Fine sand. 0.25mm – 0.06mm.

Sieve analysis for fine aggregate. | Download Table

Fine aggregate replacement of 40% FCAs, slump and bleeding of concrete with a water to cement ratio of 0.45 decreased by about 15% and 50%, respectively, which is attributed to the relatively high ...

final report

Source: PHENIX AVE. Location: CRANSTON, RI FINE AGGREGATE ANALYSIS REPORT - 2019 Lab No: 20200110 RHODE ISLAND DEPARTMENT OF TRANSPORTATION MATERIALS AND QUALITY ASSURANCE Sieve Analysis of Fine Aggregate Unit Weight and Void in Aggregate Specific Gravity and Absorption of Fine Aggregate Amount of …

IS 383 (1970): Specification for Coarse and Fine Aggregates …

2.1.2 Crushed Stone Sand - Fine aggregate produced by crushing hard stone. 2.1.3 Crushed Grace1 Sand - line aggregate produced by crushing natural gravel. . 2.2 Coarse Aggregate -- Aggregate most of which is retained on 4*75-mm IS Sieve and containing only so much finer material as is permitted for

(PDF) Compressive Strength of Concrete Made from Aggregates …

The fine aggregate from Chisang source achieved more value of average compressive strength when mix with other four different coarse aggregate sample than other three sources. Significance ...

Aggregate

These tests quantify the physical characteristics of each aggregate product from each source. Development and evaluation of all statewide aggregate related policies, procedures and specifications are continually modified to keep them current with new technologies and test procedures. Aggregates focuses on: natural sands, gravels, crushed ...

Fine and Coarse Aggregates

Asphalt Plants Approved Aggregate Sources The Materials Supplier Viewer contains the NYSDOT-Approved Sources of Aggregate for hot mix asphalt and portland cement …

Aggregate

Nagatakia et al. (2004) reported sulfate soundness losses ranging from 29.1% to 49% for RCA depending on the source, whereas the value was 9.1% and 2.6% for coarse aggregate and fine aggregate, respectively. This study also observed that when subjected to another level of crushing, the performance of RCA improved drastically.

Michigan Department Of Transportation

MDOT Aggregate Source Inventory Database. Database provided for informational purposes only. Questions, concerns or change requests can be submitted to the MDOT Aggregate Quality Unit at [email protected]. Aggregate Source Inventory - A numerical listing of all recorded sources in the Aggregate Source Inventory (ASI) with locations …

Technical Services

Source Number. Company Name Source Location. County. Test Number. Specific Gravities. Bulk (SSD) Bulk. Apparent. ABS. ASR Potential . 1- 1LFM. Norlite ... Fine aggregate produced from 7-15R. Reassigned from Region 7 to Region 1. Last Update: September 4, 2018 ...

Aggregate

Aggregate is a term for sand, gravel and crushed stone, and is the foundation of our business. Nearly 40 percent of all aggregate used in the United States goes into constructing highways and roads. Aggregate is the most abundant natural resource on earth. Crushed products are key components in the mix of asphalt and ready-mix concrete.

Aggregate Acceptance Process

The State Materials Office, Aggregate Control Unit, is assigned the task of initial aggregate source and product approval for Mines and Redistribution Terminals located In-State, Out-of-State, or Out-of-Country. For additional information on this process, please select the above link. This booklet is intended to serve as a guide for correctly ...

DIVISION III MATERIALS

COARSE AGGREGATE . 901-1 General. 901-1.1 Composition: Coarse aggregate shall consist of naturally occurring materials such as gravel, or resulting from the crushing of parent rock, to include natural rock, slags, expanded clays and shales (lightweight aggregates) and other approved inert materials with

Classification of Aggregates Based on Size and Shape

Fine Aggregate. When the aggregate is sieved through a 4.75mm sieve, the aggregate passed through it called fine aggregate. Natural sand is generally used as fine …

Impact of Fine and Coarse Aggregates from Distinctive …

River source of aggregates with periodic saline water intrusion yielded a lower compressive strength average of 18.54 MPa. Compressive strengths were monitored for 7, 14, and 28 ... Aggregate (fine and coarse) is considered an inert filler, which accounts for 60 to 80 percent of the concrete mix and 70 to 85 percent of the concrete weight ...

Aggregates

Aggregate is a granular material, such as sand, gravel, crushed stone, crushed hydraulic-cement concrete, or iron blast-furnace slag, used with a hydraulic cementing medium to produce either concrete or mortar. Types of aggregates include Coarse aggregate and fine aggregate. The aggregate of each type is further sub …

- ultra fine ball mill plants

- professional fine jaw crusher Cx 250x1200

- prices for liner bowl fine cone crusher 7 ft short head

- talc crusher fine

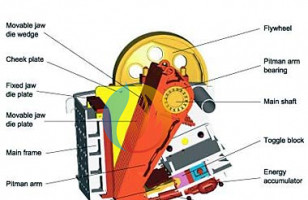

- hot sale new design fine stone jaw crusher

- ultra fine company

- raymond 54 fine grind mill

- grinding vertimill fine

- fine crusher impact

- grinding flour mill to fine powder

- tellurium fine crushing

- pe series fine stone crusher

- new design fine stone jaw crusher

- clinker fine crusher for cement

- aluminum fine crushing

- best sluice for fine gold recovery

- fine grinding dust mumbai

- ppt on replacement of fine aggregate by stone dust in concrete

- fine crushing grinding

- iron ore super fine sinter fine

- fine grinding ventilator suppliers

- professional fine jaw crusher Cx 300x1300

- stable operation fine jaw crusher

- fine gold recovery shaker tables

- difference between aggregate crushing value and 10 fine by value

- xingaung fine jaw crusher crusher

- sodium sulfate fine crushing

- ultra fine hammer mill

- bauxite fine ore price