US11007531B2

A mill for the comminution of particulate material by impact means including a shell rotating at super critical velocity and a gyrating mandrel. Material introduced to the mill forms a bed on the inner surface of the shell and is then crushed by the impact of the gyrating mandrel. ... US14/899,467 Adjustable super fine ...

Impact pulverizer, industrial impact pulverizers, fine …

The impact pulverisers are especially designed for the medium fine, and fine size reduction. The impact pulverisers meet most capacity requirements and lend themselves to a wide degree of adjustments with …

Secondary Impact Crushers – MEKA

MEKA MSI Series Secondary Impact Crusher is ideally suited to crush soft to medium hard materials down to a highly cubical, well graded product size of 0-80 mm in a single pass. Although this crusher is normally offered within a plant where tertiary crushing is also present, due to its high reduction ratio, the need for tertiary crushing can be ...

High-efficiency Fine Impact Crusher-BAILING® Machinery

High-efficiency Fine Impact Crusher . Production capacity:30-290t/h Feeding size:≤ 190mm The high efficient fine crusher as a new fine crusher has a wide range of applications with the advanced international technology. It is the most effective and reliable crushing machine at present which is applied to do fine crushing and medium crushing ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

of this series of Impact crusher lies :the final particle size with the cubic shape,no crack,fine shape .And now impact stone crusher has been applied in the field of mines, high-speed railway ...

Is It Better To Use Impact Crusher Or Cone Crusher For Fine …

Brief Introduction of Two Kinds of Granite Fine Crushers. 1. Impact crusher. The impact crusher is mainly suitable for crushing materials with low hardness …

How To Pack Crusher Fine | Crusher Mills, Cone Crusher, Jaw …

BR&D Landscape Inc. – Residential Landscaping > Walkways …. Gray Crusher Fines Path: 46 k: Gray Crusher Fines Path #2: 50.9 k: Peach Crusher Fines Path: 49.6 k: Red Flagstone Driveway Stepouts: 83 k: Buff Strip Flagstone Driveway Stepout.

Mechanical Operations Questions and Answers

Which of the following works on principle of compression and impact? a) Jaw crusher b) Gyratory crusher c) Fine crusher d) Tramp crusher ... Explanation: The stamp battery is used extensively used for fine crushing, stamp battery consists of several stamps weighing 500-1000 kg in weight. 9. The roll crushers' diameters are of ____ a) 10 inches

Fine Crusher

Xinxiang Industrial Park, Xinxiang, Henan, China. +86-373-3663285. +86-373-3663296

Understanding influence of crushers on shape characteristics of fine

Usually, different types of crushers: vertical shaft impact crusher, horizontal shaft impact crusher, cone crusher and jaw crushers are used for production of aggregates. Aggregates from different crushers may have different shape characteristics. ... AIMS test results showed that fine aggregates produced from HSI crusher had the …

Hammer Crusher | Industry Hammer Mills

【Hammer crusher in cement plant】Impact hammer crusher (cement crusher) combines the advantages of ring hammer crusher, impact crusher, optimizes the grinding chamber, obtains a better fine crushing effect. 【Coal crusher hammer】varied in different capacity requirements, the coal crusher hammer type generally have small capacity …

Solved Which of the following works on the principle of | Chegg

This problem has been solved! You'll get a detailed solution from a subject matter expert that helps you learn core concepts. Question: Which of the following works on the principle of compression and impact? Select your answer A Jaw crusher B B Fine crusher с Gyratory crusher D Tramp crusher.

Fine Crusher|Henan Zhenyuan Science & Technology Co., Ltd

By taking the advantages of hammer crusher and impact crusher, this machine can highly improve working efficiency and reduce energy consumption. High-efficiency fine crusher has significant advantage in the filed of crushing soft material features reliable operation, simple structure, convenient maintenance, high capacity, long service life.

Fine Crushing Plant With Roll Crushers

After shearing and meshing (ultra-fine crushing), it is crushed into the required particle size and discharged from the discharge port, The middle two crushing rollers are common. For more fine crushing machines, please contact us, and we will choose the best right rock crushers for you. sales@jxscmine. +86-.

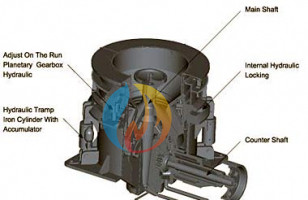

hydraulic cone crusher,cone crusher machinery,hydrocone crusher…

0086-371-63769782 sales@greatwallcrusher. The HCC Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgy and so on. It can crush materials with middle and high hardness such as, ironstone, copper ore, granite, basalt, cobblestone, marble, limestone and so on.

10 Ways to Get the Most Out of Your Mobile Impact …

Excessive fines inside an impact crusher is like sandblasting. Your impactor wear parts such as hammers and wear plates will be chewed up quickly. To counter negative effects …

Crushers and Their Types – IspatGuru

Roll crusher is suitable for fine crushing. The roll crusher uses compression to crush materials. Reduction ratio is 2 to 2.5 to 1. Roller crushers are not recommended for abrasive materials. Hammer crusher. ... Impact crusher can also be equipped with a bottom screen, which prevents material leaving the crusher until it is fine enough to pass ...

Fine Jaw Crushers

EV Hammer Impact Crusher FL Strike-Bar™ Crusher Back. Roller crushers and sizers. ABON® Low Speed Sizer Double roll crusher ... Essa® JC1250 Fine Jaw Crusher – the scaled down and more affordable version of our fine jaw crushers. Evolved from an intensive two-and-a-half-year research and development program to present power and ...

Crusher

The impact crusher (Fig. 13.15) employs high-speed impact or sharp blows to the free-falling feed rather than compression or abrasion. It utilizes hinged or fixed heavy metal …

How does an impact crusher work? | RUBBLE MASTER

There are 2 main types impact crushers - horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers. Horizontal Shaft Impactor (HSI) The horizontal …

Impact crusher, Impact crusher direct from Henan Baichy …

Top Brand 100-200 Tph Stone Crushing Machinery Impact Crusher, Small Gravel Impact Crusher Machine, Impact Crusher For Sale. $21,000.00 / set. 1 set (Min. Order)

Impact Crusher For Sale

APF-V impact crusher is also called a three-chamber impact crusher, which is suitable for medium and fine crushing. Because the APF-V impact crusher has three counterattack chambers, its rear chamber has leveling function. Therefore, its discharge particle size will be more uniform, and the proportion of fine particle size is large.

Impact Crusher

Impact Crusher. The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of …

Used Blow Crusher Jaw Crushers for sale. Baichy equipment

Impact Crusher jaw crusher Impact Fine Crusher. new. Manufacturer: The Nile Impact Crusher jaw crusher Impact Fine Crusher Product Description The impact crusher is designed as a three-chamber crushing zone. It can crush all kinds of coarse, medium and fine materials with compressive str...

Cone Crusher Liners | Manufacturing and service of Gyratory

Our operations span the globe and we are close to 11,000 employees, present in more than 60 countries. In 2022, FL generated revenue of DKK 21.8 billion. About us. Contact. FL A/S Vigerslev Allé 77 2500 Valby, Copenhagen Denmark. +45 3618 1000 info@fl. Get in touch.

Impact Crusher, Horizontal Shaft Impact Crusher

The impact crusher uses horizontal and high-speed moving rotors to crush materials, which can help the producer to obtain a fine-grained and evenly distributed product. Impact crushers are widely used in the production of construction aggregates and crushing construction and demolition waste. GEP Ecotech's impact crusher uses high-strength ...

Hammer Mill Crusher & Grinder

A certain amount of impact breaking does take place between hammers and grates, but this is secondary to the work done against the involute plates. On friable material this machine will deliver a medium fine (0.25″ to 3/8″) product with some, or even all, of the grates removed. Capacity of Hammer Mill Crushers

Vertical spindle impact fine crusher

The utility model discloses an impact-type fine crushing machine with a vertical shaft, which is composed of a barrel body 1, a machine cover component 2, a belt pulley 4, a main shaft 5, a rotor component 12, a machine base component 16 and a lubricating-oil circulating system 13. The utility model has the advantages that the …

Jaw Crusher VS Impact Crusher

2. Impact crusher is usually used as a medium-fine hardness crusher, such as limestone, concrete, it has good crushing efficiency of some brittle material. It mainly crushes the small material discharge from the jaw crusher. In general, the jaw crushers are placed before the impact crusher. 2. Capacity. 1.

Baichy Heavy Industrial Machinery Co., Ltd

Baichy is a factory supplier of mining machinery, mainly focused on Stone crushers, Mobile crushing plants, Powder grinding mills, and Mineral processing equipment. Contact us 86

VWHP

crusher, impact crusher and roll crusher, etc. Crushing force used by this kind of crushing system is not applicable to biomass crushing. Although there are some small crushers for fodder and traditional ... fine crusher to conduct secondary crushing, particles with small particle size (d<250µm)after shocking, grinding and shearing would ...

- ultra fine ball mill plants

- talc crusher fine

- ultra fine company

- ultra fine grinding isa mill

- raymond 54 fine grind mill

- grinding flour mill to fine powder

- cement fine grinding versus power per ton

- fine crushed quartz sand

- tellurium fine crushing

- pe series fine stone crusher

- quartz sand fine

- super fine griding milling

- fine aggregate source

- clinker fine crusher for cement

- aluminum fine crushing

- fine powder production

- best sluice for fine gold recovery

- fine grinding screen

- fine grinding dust mumbai

- ppt on replacement of fine aggregate by stone dust in concrete

- fine crushing grinding

- professional fine jaw crusher Cx 300x1300

- stable operation fine jaw crusher

- difference between aggregate crushing value and 10 fine by value

- xingaung fine jaw crusher crusher

- high efficient fine crushing jaw crusher

- ultra fine hammer mill

- fine coal directory

- bauxite fine ore price